Raller roller cnc cnc mochini oa lirosa

Tlhaloso ea Sehlahisoa

1. Kemiso ea botsoalle e hlophisehileng ea li-cnc.

2. Sisteme ea morao-rao e ka sebetsa habonolo ea ho sebetsa habonolo, e kenyeletsang li-cutler tsa rabara

3.

4. Tsebiso e tukang e fetoloa.

5. Ho ba le mesebetsi eohle ea lenaneo la rona la PSM la PSM

1) Lisebelisoa tse tloaelehileng tsa PSMT letoto li kenyelletsa:

AA AAHILETER Sistimi e nang le likhohola e potoloha

B.MOETERED TailStock

C.VALIPLE E ETSAHETSENG LE LITLHAKISO TSE KHOLO

d.frofnt le morao-rao li-tables tse sebetsang tsa thepa

ea topolle e tsamaeang ka kotloloho e kentsoeng ka morao

2) E etselitsoe ka ho khetheha ho nkela sebaka sa meralo ea meralo ea li-granding tsa meralo ea roller.

3) Litafole tse peli tse mahareng tse kopaneng ho netefatsa ts'ebetso e nepahetseng le botsitso bo sebetsang.

4) Max. Tepe ea Linear ea Hlooho ea Grinding e felile 90m / s. Ts'ebetso ea tlhahiso e eketsehile haholo mme boholo ba geometri bo tiisitsoe.

5) Sesebelisoa se tsoetseng pele se kopantsoeng se hlahisa data ea ho sebetsa mme e fana ka thuso e sebetsang ea ho laola boholo ba grind e ka ntlafatsoang ka kopo.

6) Ka khona ho netefatsa keketseho ea ts'ebetso ea barekisi ba rapeloang bo khethehileng.

| Lebitso | Mohlala | Tšepe / rabara | Da. | Leng | Boima | ||

| Rabara r brinding mochini | PSM-4020 / D | Che / e | 400 | 2000 | 500 | ||

| Rabara r brinding mochini | PSM-6030 / D | Che / e | 600 | 4000 | 2000 | ||

| Rabara r brinding mochini | PSM-8040440 / D | Che / e | 800 | 4000 | 5000 | ||

| Rabara r brinding mochini | PSM-1250 / D | Che / e | 1000 | 6000 | 6000 | ||

| Rabara r brinding mochini | PSM-1460 / D | Che / e | 1200 | 8000 | 8000 | ||

| Rabara r brinding mochini | PSM-Setsebi | Che / e | Boikhethelo | Boikhethelo | Boikhethelo | ||

| Re bua ka | D: Khomphutha ea indasteri T: skrineng sa ho ama | ||||||

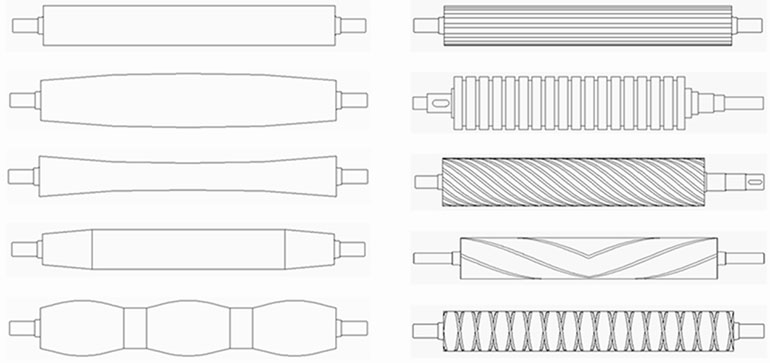

Roller Profil

Sistimi e na le ts'ebetso ea ts'ebetso ea ho lokisa hohle, e nang le merero ea 35 ea ts'ebetso:

E na le mefuta e 5 ea sebopeho sa sebopeho, mefuta e 5 ea ho jella tšebetso ea lipalesa (Hammer Groove, hard con ka ho latellana.

Kopo

Motheo ho The Mochine oa mantlha oa PUST PSM - Setopa sa Psm-CNM o ntlafalitsoe ka ho fetoloa mofuta oa mofuta o khabisitsoeng le tsamaiso ea taolo. CON Sistimi ea CNC ke software e hlophisehileng ea dijithale ea dijithale bakeng sa ts'ebetso ea roll. Jinan Of Power Ruller Lisebelisoa tsa Ke Jinan Power Litšobotsi tsa eona tsa botsebi ke tsona tse ntle ka ho fetisisa khoebong ea meputso. Ka lebaka la ts'ebetso ea sistimi e potolohileng, e ka etsa hoo e ka bang litaba tsohle tsa li-roller. Mohlala, moqhaka oa paro -lic oa paronolic, coscaring moqhomane, ea ponngoeng, herring, e otlolohileng, groove e otlolohileng le mefuta e meng le likhakanyo tse ling.

Litšebeletso

1. Ts'ebeletso ea ho kenya sebaka sa marang-rang e ka khethoa.

2. Tšebeletso ea Tlhokomelo ea Bophelo Halelele.

3. Tšehetso ea inthanete e sebetsa.

4. Files ea Teecini e tla fanoa.

5. Ts'ebeletso ea boikoetliso e ka fanoa.

6. Likarolo tsa sebaka sa phomolo le ts'ebeletso ea ho lokisa li ka fanoa.