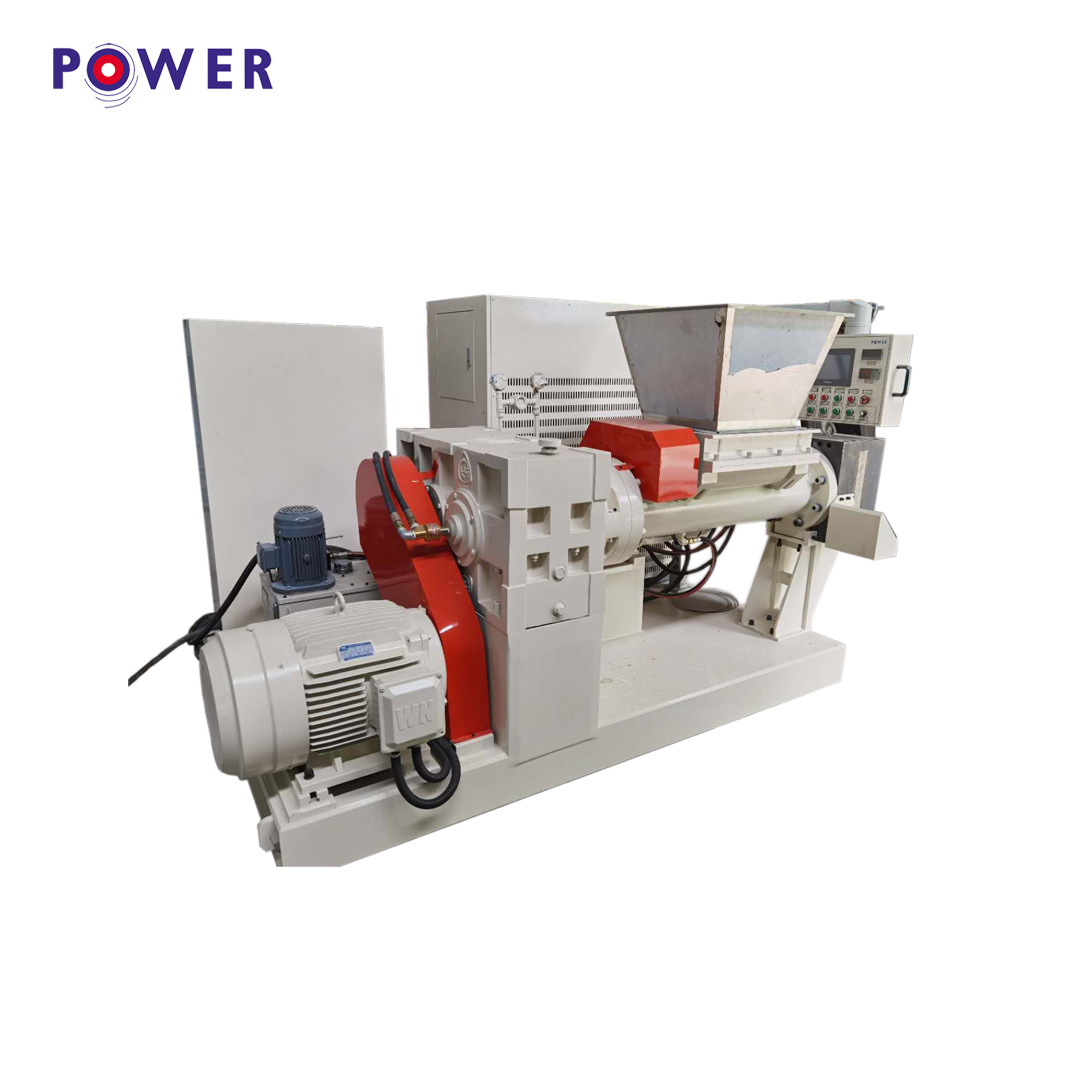

Kenyelletso: Tlhahlobo ea filimi ke lisebelisoa tsa bohlokoa li sebelisoa haholo indastering e fapaneng ea lits'ebetso tse arohaneng tse tiileng. Sengoliloeng sena se tšohla bohlokoa le mesebetsi ea mechine ea khale, e totobatsang melemo le bohlokoa ba likarolo tse fapaneng.

Ts'ebetso ea khatiso ea sefako: Mochine oa khatiso o etselitsoe ho tlosa likaroloana tse tiileng ho motsoako o tiileng, ho theha li-antiard tse hlakileng le tse arohaneng. E na le letoto la lipotoloho tsa faele le liforeimi tse nang le masela a filter ho tima likaroloana tse tiileng mme o lumelle mokelikeli ho feta. Khatello e sebelisitsoeng ho nts'etsapele boholo ba mokelikeli ho tloha selloeng ha o ntse o boloka likaroloana tse tiileng.

Likopi ts'ebetsong ea lik'hemik'hale: indastering ea lik'hemik'hale, likhatiso tsa meralo li sebelisetsoa ho arola likaroloana tsa lits'ebetso tse fapaneng tse kang ho ngola lipalesa, litlhaloso le tlhophiso. Sena se tiisa tlhahiso ea lik'hemik'hale tse phahameng haholo tse se nang litšila ebile li etsa bonnete ba ho latela litekanyetso tsa boleng bo tlaase. Mechine ea mechine ea khale e sebelisoa hangata tlhahisong ea meriana, daes, picts le lintho tse ling tsa lik'hemik'hale.

E sebelisa ka meepo le metallurgy: indasteri ea meroho le ea metalligy e itšetlehile haholo ka ho arohana le karohano ea metsi le slurries. Li sebelisoa ho ntša lintho tsa bohlokoa, lisebelisoa tse fapaneng tsa litšila, 'me li tlosa metsi bakeng sa ho sebelisa hape. Mechine ea khale ea khale e bohlokoa ho hlahiseng liminerale ea liminerale tsa liminerale, li-ores le tšepe li tsepama. Ka ho tlosa likaroloana tse tiileng mme ho khutlisa khatello ea metsi, likhatello tsa sefahleho li kenya letsoho ts'ebelisong ea lisebelisoa le tšusumetso e tlase ea tikoloho.

Likopo libakeng tsa lijo le tsa ho li fihlela: lipapaling tsa lijo le tse se nang linyeeletsing li bapala karolo ea bohlokoa ho netefatsa boleng le polokeho ea lihlahisoa. Li sebelisetsoa ho hlakisa lino tse kang mele, bine, biri le asene, ho tlosa litšila le botsitso ba ho holisa litšila le ho etsa hore ho be le botsitso le ho hlasimolla sehlahisoa. Ts'ebeliso ea likhatiso tsa sefa litoropo tsa ts'ebetso ea lijo e thusa ho boloka litekanyetso tse phahameng tsa bohloeki ebile li nka bophelo bo senyehileng ba lihlahisoa tsa lihlahisoa tsa lijo tse senyehang tsa lijo tsa lijo tse senyehang.

E sebelisa kalafong ea metsi a litšila: likhatiso tsa khale li sebelisoa haholo lijalo tsa kalafo ea metsi a senyehileng bakeng sa karohano ea metsi bakeng sa ho putlama ha metsi. Ba tlosa metsi ka tšohanyetso ho tsoa ho tloha sethaleng, ba fokotsa molumo oa ona le ho nolofatsa ho lahla kapa ho sebelisa hape hape. Likhatiso tsa filthara li boetse li a thusa ho hlaphoheloa thepa ea bohlokoa ho tloha ho litšila tsa indasteri, metsi a sirelletsang le ho tsitsipana.

Melemo ea Likhatiso tsa Filter:

Ts'ebetso e phahameng ea Tlhahlobo e Phahameng: Khothatso ea Filter e fana ka karohano e nepahetseng ea metsi, e netefatsa sekhahla sa ho foka le ho hlaphoheloa ka metsi.

Ho fapanyetsana thepa: Ho hatella ha litlhare ho ka sebetsana le thepa e ngata, ho tloha ha likaroloana tse ntle ho ea Coasdes, e etsa hore li lokeloe lits'ebetso tse fapaneng tsa indasteri.

Setheo se Molemo: Tšebeliso ea likhatello tsa filthara e thusa ho fokotsa molumo oa litšila, litšenyehelo tse tlase tsa ho lahla le kalafo, le ho ntlafatsa ts'ebetso ea ho sebetsa ka kakaretso.

Matlafatso ea Tikoloho: Khatiso ea Sefatho e khothalletsa mekhoa e tsitsitseng ka ho fokotsa ts'ebeliso ea metsi, ho fokotsa moloko oa litšila, le ho nolofalletsa ho hlaphoheloa ha lisebelisoa tsa bohlokoa.

Phetha: Mochine oa likhomo ke lisebelisoa tse sa tloaelehang indastering ea indastering e fapaneng, li fana ka karohano le linyeoe tse atlehileng tsa metsi le tharollo ea taolo ea litšila. Their applications in chemical processing, mining and metallurgy, food and beverage production, and waste water treatment are critical for ensuring high product quality, resource conservation, and environmental safety. Ka katleho ea bona, tšebeliso ea litšenyehelo, litheko tsa litlhahiso li tsoela pele ho bapala karolo ea bohlokoa ho ntlafatsa tlhahiso ea indasteri le ho khothaletsa tlhahiso e akaretsang.

Poso: Hlakubele-02-2024