Tsamaiso ea tlhahiso ea li-roller ea rabara ka kakaretso e latela mehato e mengata, ho kenyelletsa ho hlophisa lisebelisoa tsa rabara, ho thellela lits'ila tsa rabara, lisosa tsa li-roller tsa rabara, le tšoaro e holimo. Ho fihlela joale, likhoebo tse ngata li ntse li itšetleha ka tlhahiso ea puo lipakeng tsa tlhahiso ea puo. Lilemong tsa morao tjena, ka nts'etsopele e tsoelang pele ea enjene, e fetoha le mahlale a moea, ralense ea roller e beha tlhahiso ea lieta le ho kenella ka potlako. Kahoo, tlhahiso e tsoelang pele e tsoang meralo ea rabara ho ea boqapi ebile e finyeletsoe haholo, e atlehile haholo 'me u ntlafatsa tikoloho e sebetsang le ho ba le matla a tšebetso. Ka lebaka la ho ba sieo ha litšila tsa lehlabathe, le li-bubble holim 'a maqeba a rabara, likoluoa, mapetsong, kapa lipula tsa lehae. Ka hona, feela ka ho boloka li-ralle tsa rabara li hloekile haholo ebile li le hantle ke ts'ebetso ea tlhahiso ea lihlahisoa le theknoloji ea boleng bo lekanang, e ka tiisa hore lihlahisoa tsa bongata li ka netefatsoa. Hajoale, motsoako, oa ente, o ente

Ho hlophisoa ha thepa ea rabara bakeng sa ts'ebetso ea tlhahiso ea rarabele

Bakeng sa barekisi ba rabara, ho kopanya lintho tsa rabara ke mohato o nyatsang ka ho fetisisa. Ho na le mefuta e fetang 10 ea lisebelisoa tsa rabara tse sebelisoang bakeng sa li-rabber tsa tsoekere, li laetsana ka lisebelisoa tse khethehileng, tse nang le litlolo tsa mobu (0-90), ho qala ka bongata. Mokhoa o tloaelehileng ke ho sebelisa mochini o kopanyang oa rabara o bulehileng ho kopanya le ho sebetsa mefuta e fapaneng ea metsoako ea rabara. Mochine o kopanyang oa rabara ke mofuta oa mochini o kopanyang o nang le barekisi ba pepesitsoeng ho lokisa lieta tsa rabara,polasetiki e ntlafatsang, 'me e bina lisebelisoa tsa rabara. Leha ho le joalo, tsena ke mofuta oa lisebelisoa tsa polasetiki. Lilemong tsa morao tjena, likhoebo li fetohile tse ntseng li phahama haholo ho sebelisa li-mochineng tsa kahare ho hlahisa lisebelisoa tsa rabara ka ho kopanya thepa.

Kamora ho fihlela junifomo e kopanyang, lisebelisoa tsa rabara li hloka ho hloekisoa mochini oa litšila ho felisa litšila ka har'a thepa ea rabara. Ebe u sebelisa calender, e se nang chelete e ngata, le ho latola ho etsa filimi kapa strip ntle le bubble kapa litšila tse sebelisetsoang ho theha li-raber. Pele u theha, tlhahlobo e bona e nang le pono e hlakileng e lokela ho etsoa lifiliming tsena le li-rabara tse ngata, 'me bokahohle bo lokela ho bolokoa bocha ho thibela ho latela moea le boqapi. Malinyane a tsoang lifiliming le a rabara ha a lokela ho ba le litšila le li-bubble, masoba a lehlabathe a ka hlaha ha a ntse a tsitsa ka mor'a ho ba le likotsi.

Roller Roller e thellang ts'ebetsong ea tlhahiso ea barekisi ba rabara

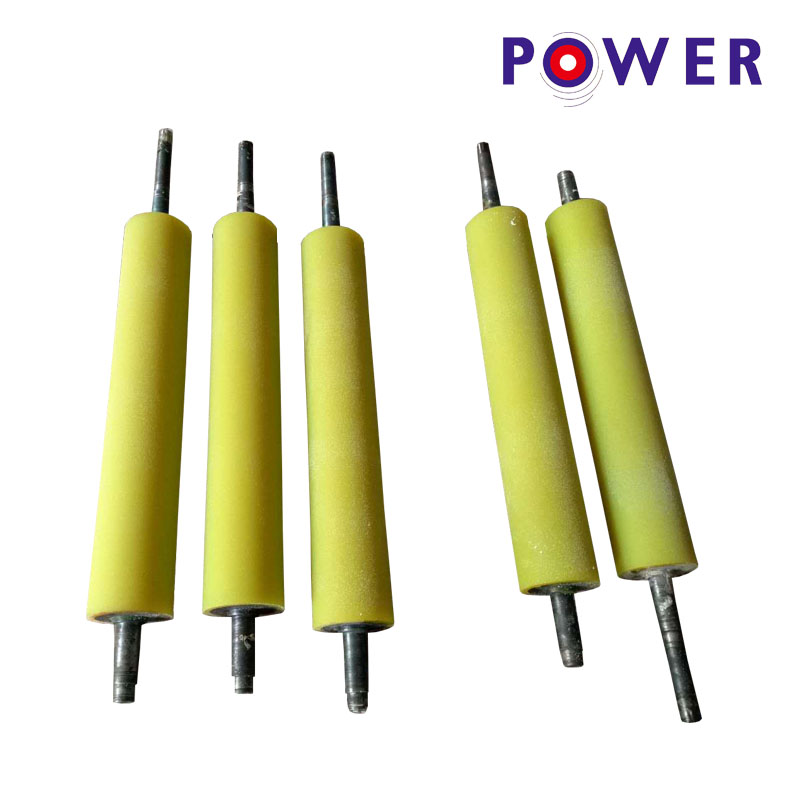

Mofoko oa li-raroli-li-racher o kenyelletsa ho khomarela le ho phuthela rabara ka mokotleng oa tšepe. Litloaelo tse tloaelehileng li kenyelletsa ho kuta sepolelo, ho iphetsana, ho bopa, ente ho bososela le ho bonya. Hajoale, likhoebo tsa lapeng li itšetleha haholo ka ho bopa mokholu oa mochini o nang le mochini, ha linaha tse ling tsa kantle ho naha li atlehile ka mokhoa oa mantlha. Literene tse kholo tsa tlhahiso le tse bohareng tsa tlhahiso li sebelisitse mokhoa oa ho qotsa le mehala e feteletseng ho tiea le sebopeho sa rabara kapa tlhahiso ea foromo. Ka nako e ts'oanang, nakong ea boliba, litlhaloso, boholo, le ponahalo ea ponahalo e laoloa ka boeona ke microcoputer, roller China,Ba bang le bona ba ka ba ba qhekelloang ba sebelisa mekhoa e nepahetseng le mekhoa e sa pheleng ea motho ea sa pheleng ea motho ea mo phethisang.

Tšebeliso ea Extlo ea ho fetoha le Microcompiut Inthomatiatic Taolo e Laolang e ka tlosa li-bubble tse ka 'nang tsa fokotsa li-bubble le ho fokotsa matla a basebetsi ho isa moo nka khonang. Bakeng sa ho thibela Deformation nakong ea ho senya rolara ea rabara ebe u thibela moloko oa li-bubble and spongs, hina rabara khatello ea naha,Mokhoa o boima oa khatello le ona o lokela ho sebelisoa ka ntle bakeng sa mokhoa o hlabang oa mokhoa o koalang. Hangata, lesela le 'maloa la k'hothone kapa nylon le thabisitsoe ka sefahleho sa rabara, raber roller e thata,ebe o behiloe mme o hatelloa ka terata ea tšepe kapa fiber.

Bakeng sa barekisi ba rabara ba banyenyane le ba banyenyane ba babeli ba rarolloang joalo ka ha ho laeloa libuka, ente bo bopang, ho tšosa ka ente, 'me ho tšoloha ho ka sebelisoa. Bakeng sa ho ntlafatsa ts'ebetso ea tlhahiso, mekhoa e bomang e se e sebelisoa haholo, 'me ho nepahala ho phahame haholo ho feta mekhoa eo e seng ea bomahang. Ente le ho hatella raese ea rabara e tiileng, hammoho le ho tšolla rabara ea metsi, e se e le mekhoa ea bohlokoa ka ho fetisisa ea tlhahiso.

Nako ea poso: Jul-25-2024